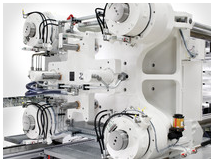

MX machines demonstrate why KraussMaffei is among the market leaders in the area of heavy machinery. In the clamping force sizes ranging from 8,500 to 40,000 kN you get a very compact, high-performance production system that features short machine times, fast cycles and a high output of molded parts. The series has a modular design and offers a wide range of configuration options. This way you can quickly upgrade the standard machine without any problem and optimally adapt it to your production requirements.

The twin-platen clamping unit of the MX series has a compact design, produces quickly and requires little maintenance in operation. The rugged mechanical system and stable platens with excellent rigidity offer optimal mold support with high dynamics. The locking system is designed for the shortest cycles with precise positioning. Thanks to absolute platen parallelism, the mold is protected and best part quality is ensured.

|

Encapsulated locking unit and locking cylinder for extremely short cycles. The moving platen is manufactured in a box structure and optimized according to FEM (finite element method). |

|

The force flow and weight-optimized sliding shoes ensure that the moving platens are guided securely. |

|

Premium-quality material combinations increase durability |

|

Molds are protected in every position thanks to the guided tiebars. |

|

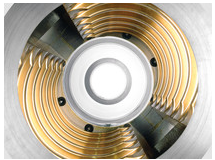

Injection unit is a key element of our machines. It provides maximum precision and process consistency. |

|

As an expert in the plasticizing system, we have an option to screw up to 265 diameter at our wide product range.at our wide product range, scale up to 265 mm diameter screws are our very rich varieties to fit your preference. |

Usability is our top priority

With the intuitive MC6 control system, KraussMaffei offers a system that improves every facet of machine operation for users. The experienced software developers at KraussMaffei focus on functions that are usable and simplify navigation. All series are equipped with the MC6 control system.

Based on the credo "reaching the destination as quickly as possible", a clear overall concept with individually configurable favorites bars is produced. In order to ensure easy use, the machine keyboard only shows the buttons that can be selected in a given machine operating status.

SplitScreen teknolojisi, MC6 kontrol sisteminin önemli unsurlarından biridir: Bu bölünmüş ekran gösterimi sayesinde, en önemli üretim süreçlerini aynı anda görebilirsiniz. Örneğin, enjeksiyon işlemini gerçek değerli çevrimlerle aynı anda izleyebilirsiniz.

SplitScreen technology is one of the special highlights of the MC6 control system: Thanks to the split-screen display, you can view the most important production processes simultaneously. For example, you can monitor the injection process at the same time as the actual value cycles.

ProcessDesigner: Clear layout

The integrated ProcessDesigner tool provides a clear visual presentation of all current processes and enables users to modify them, depending on requirements, by means of simple drag-and-drop or swiping movements.

In keeping with our overall energy-efficient design, the MC6 control system has an "Eco button." This allows you to configure the machine for optimal energy efficiency at the push of a button.

|

|