Packed to the brim with performance: solutions for logistics and large packaging applications

|

Numerous companies from the packaging and logistics industry are counted among the long-time customers of KraussMaffei. You too can benefit from the extensive machine program, which serves the specific requirements of the industry.

Through its combination of reliable machine designs with innovative technologies, KraussMaffei operates as an one-stop shop for individualized production solutions. In addition to a global network of moldmakers and peripheral providers, the individualized production solu-tions are based on one-of-a-kind KraussMaffei machine technology:

- MX series: These machines with a closing force up to 5.500 tons are the largest fast machines available on the market

- GX series: These machines which are at the segment of middle closing force of 400 to 900 tons are the world’s fastest systems containing dual plates

- CX series: Thanks to two-platen technology, the machines of the CX series are readily accessible and very compact. They are available in small (350 to 1600 kN) and medium clamping forces (2000 to 6500 kN).

- PX series: These machines with a closing force from 50 tons to 200 tons are optimal machines, especially for manufacturing of packaging and technical parts.

- Automation: Complete integration with our own linear or 6-axis technology

|

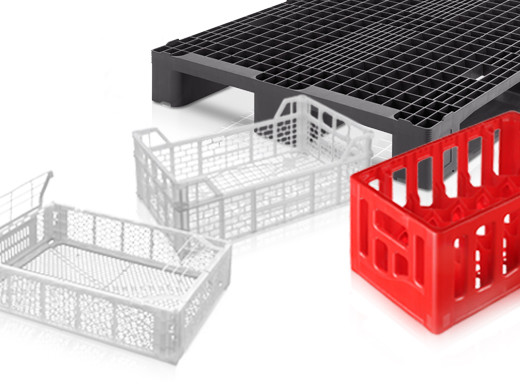

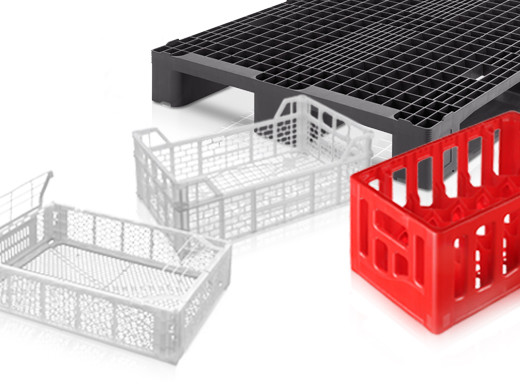

Packed to the brim with performance: solutions for crates and buckets

|

Low unit costs are a crucial factor in the production of crates and buckets. Products from the GX series are ideal for this use:

|

- Short cycles thanks to the best machine dynamics and the shortest dry cycles

- Heavy-duty HPS-S screws for consistently leading plasticizing performance/revolution

- High platen parallelism ensures faultless molding, uniformly excellent unit appearance and low mold wear

- KraussMaffei Automation offers faster demolding and clear-ance for optional accompanying processes such as in-mold-labeling, insertion of RFID labels, etc.

- Complete integration of injection molding technology and automation and Adaptive Process Control (APC)ensure high process reliability and easy operability

|

|

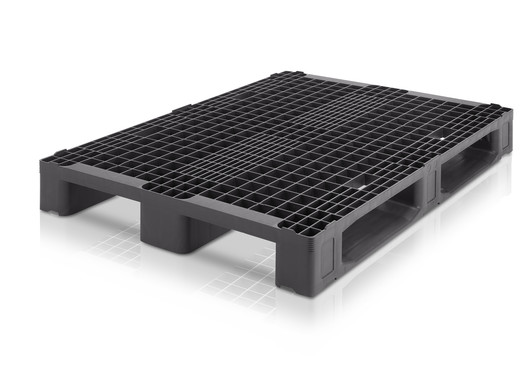

Major steps forward in performance: solutions for pallets and large containers

|

For logistics applications as e.g. pallets defined mechanical properties such as static or dynamic load are essential. The MX series with its repeatble plasticizing and filling abilities together with their preecise demoulding capabilities ensure the production of big sized parts with defined properties at optimized cost.

|

- Short cycles with excellent two-platen machine technology

- Patented, globally unique solutions for processing high filler contents up to 50%

- Implementing high shot weights for first-class homogenization of various mixtures of recycled materials or additives

- Rugged, reliable machine technology ensures high platen parallelism as standard and guarantees a uniformly high availability/yield of OK parts in the high performance area and for large opening strokes

- KraussMaffei Automation offers solutions for complex downstream equipment and, thanks to complete integration, the production system remains transparent and easy to use at all times

|

|